Polyester, fiberglass and composite materials

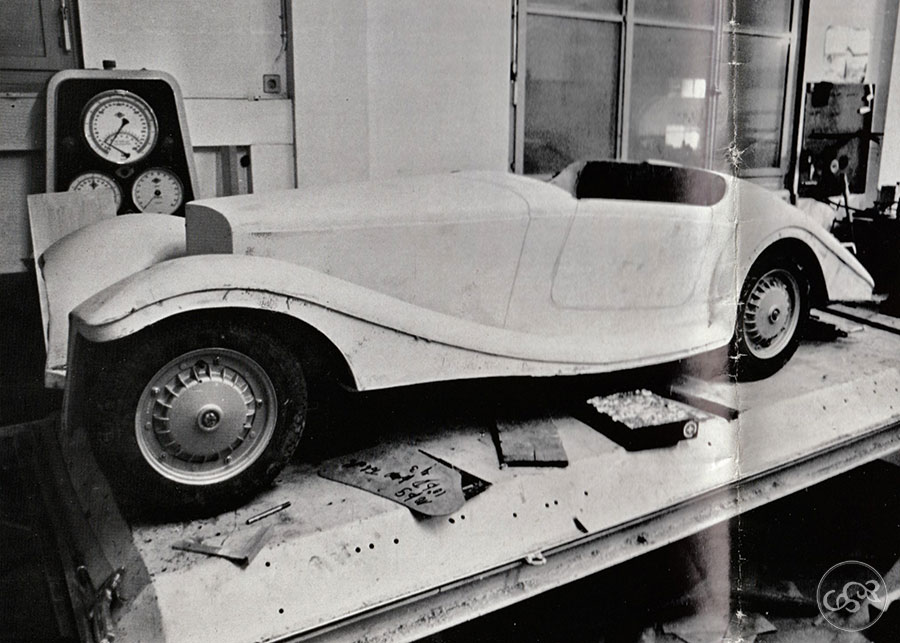

Franco Sbarro began working with polyester and fiberglass when he built his first prototype in 1959. Since then, he has become a specialist in this technique, which he now passes on to his students at the Espera school.

A clumsy start

Franco Sbarro's first prototype was initially bodied using parts borrowed from a Jovet-Javelin. But the result wasn't up to scratch, and Sbarro went on to make a polyester and fiberglass body, without a mold, by stretching strips of fiber (laizes) over a round wire skeleton. The result was rather disappointing, so he made a mold from parts taken from a Berkeley. The mold was then reworked to obtain the desired curves. Once again, and by Franco Sbarro's own admission, the result was not a happy one! We had to wait until 1965 to see a more elaborate Sbarro, the Filipinetti coupé.

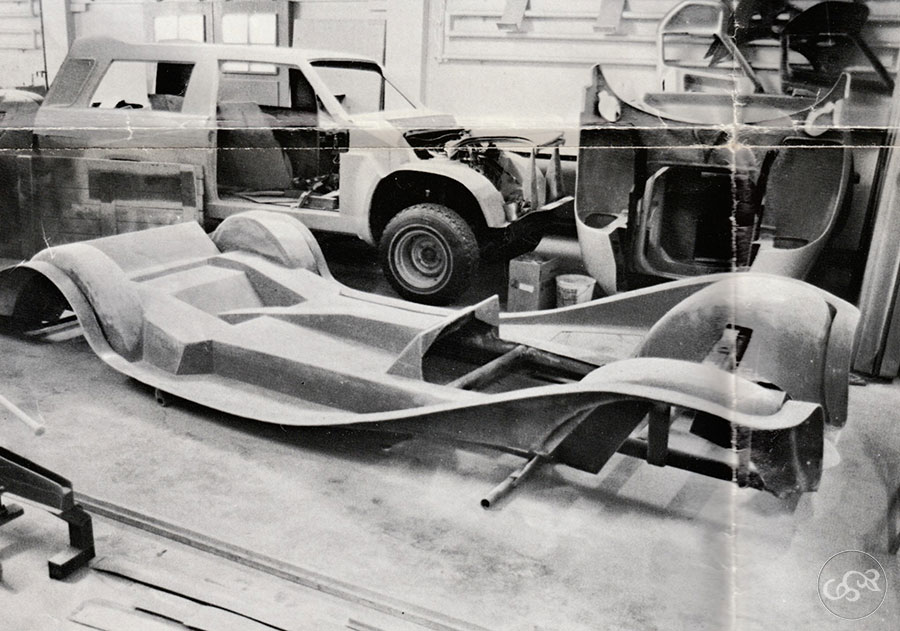

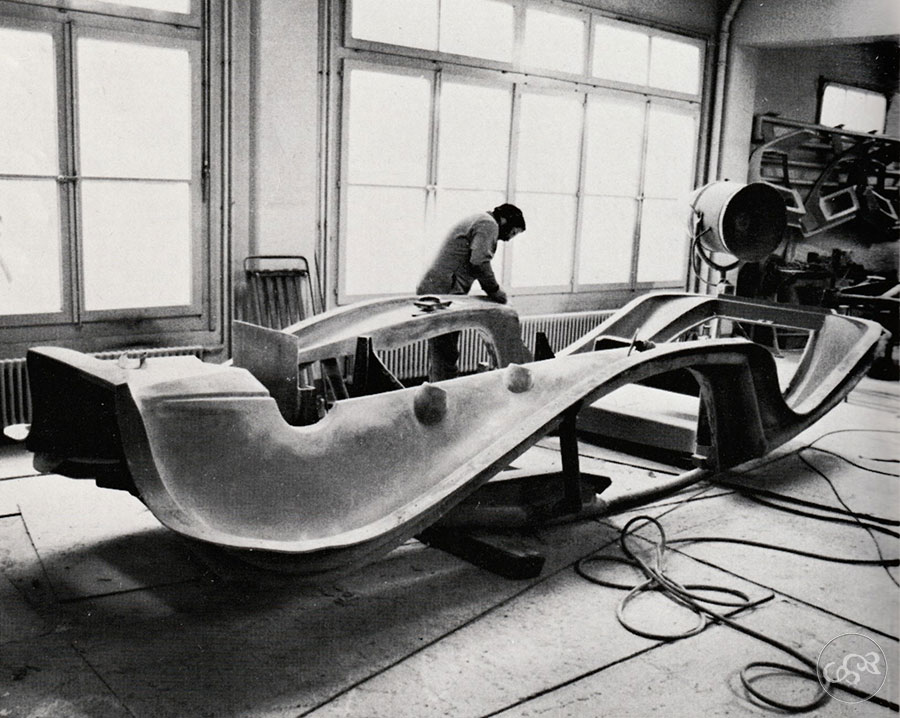

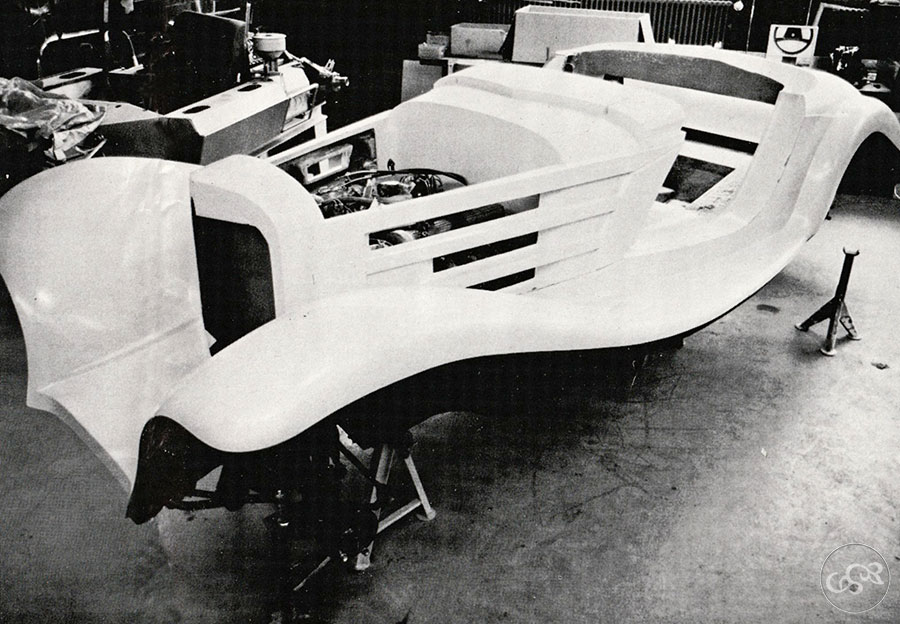

The steps involved in bodybuilding

As I'm by no means a specialist

in fiberglass and polyester, I'll try to give a rough outline

of the technique used by the Espera students, from what I

gather from the photographs and comments left on their

Facebook page.

A wooden marble will serve

as a reference for the construction of the master, made up of

a wooden core and polyurethane foam blocks. The master is the

part used to create the mold for the future body. The foam

blocks are positioned, trimmed and glued to meet the defined

dimensions.

From this clay model, we make the master, a 1:1 scale model in polyurethane foam. This master is prepared: resinated, then sanded, so that the putty can be applied with a spray gun to ensure clean surfaces when the mold is created. The mold is then carefully polished and gel-coated.

In brief

1- Franco Sbarro has been using fiberglass and polyester since 1959.

2- Inexpensive body-building technique

3- Still used by Espera students.