Dual Frame

Two years after the presentation of the famous orbital wheel, the hubless wheel, Franco Sbarro unveils the Helios program and the Dual Frame chassis concept.

The Dual Frame principle

The idea is to separate "structural dynamic

functions from structural protection and comfort functions".

In practice, this means dividing a car into two distinct

parts:

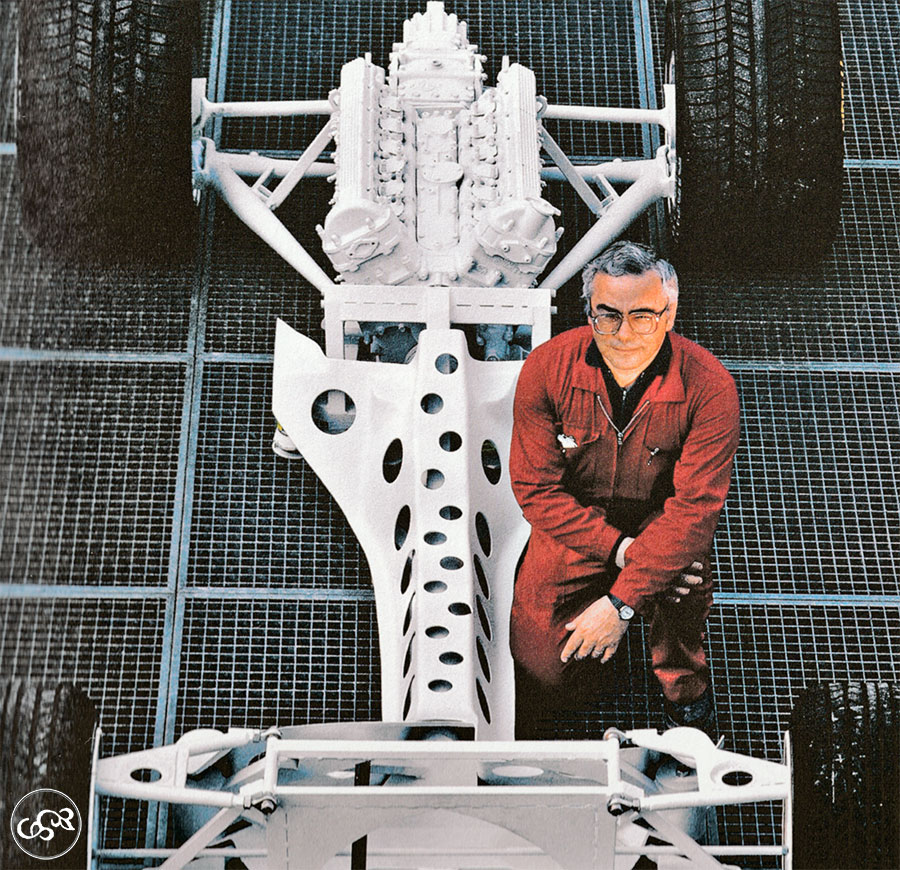

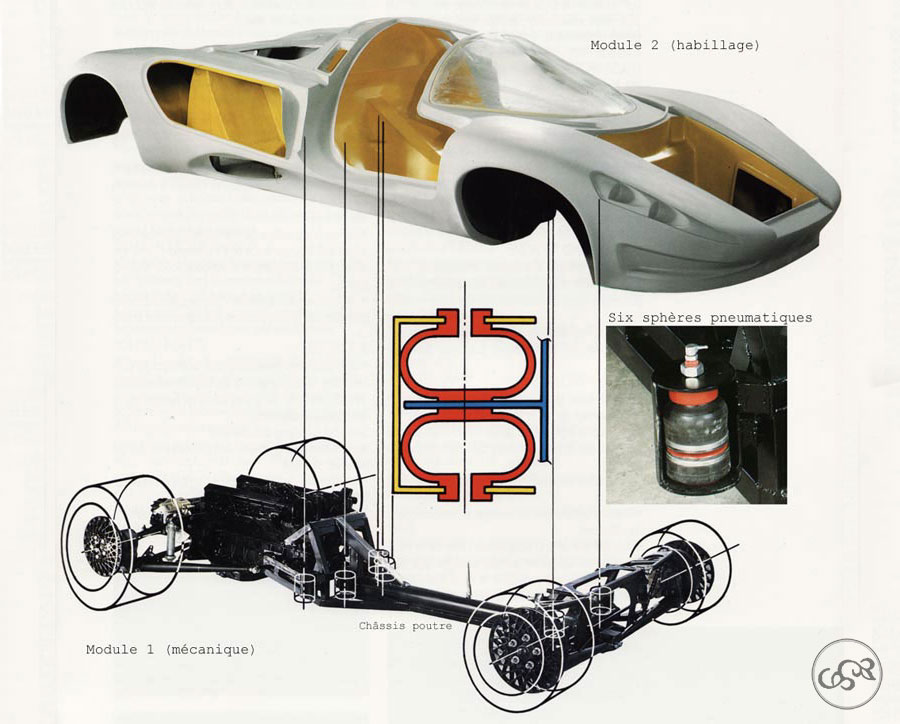

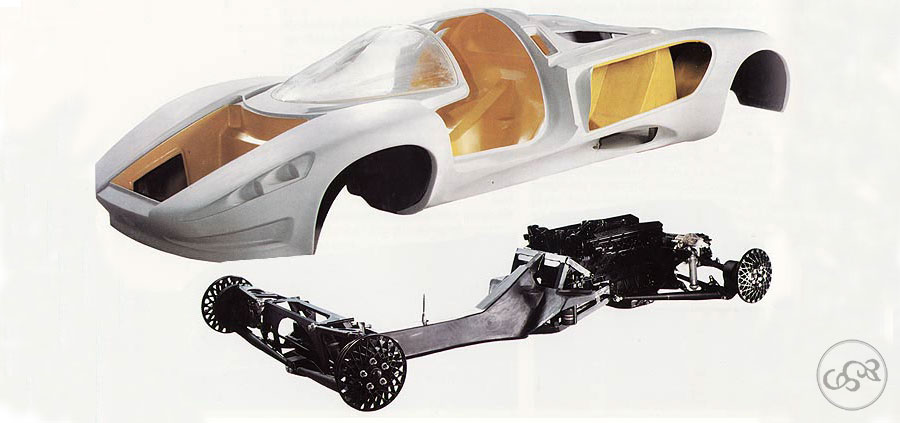

A mechanical part (module 1, known as active safety)

comprising the mechanics and the rolling structure. An

engine-gearbox assembly, attached to a central-beam chassis,

which includes all suspension components, guaranteeing

rigidity and precision;

a trim section (passive safety module 2) corresponding to the

bodywork, made of composite materials, and the passenger

compartment. Between the two modules are pneumatic spheres,

comparable to double-acting cylinders. These spheres inflate

and deflate according to road conditions or driving style.

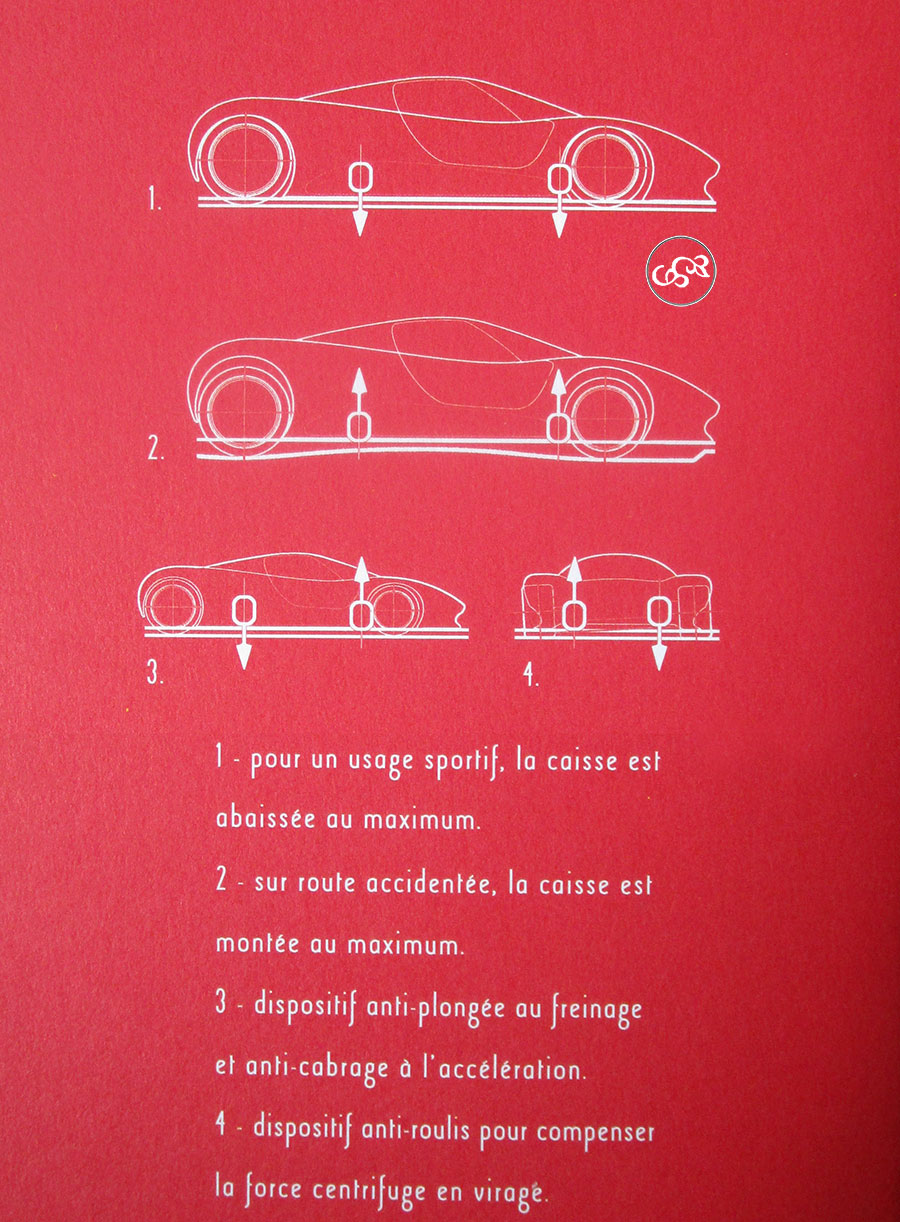

Thanks to this pneumatic system, the ride height can be varied

to eliminate pitching under acceleration, diving under braking

and rolling when cornering.

The benefits of Dual Frame

First of all, weight savings: fewer

mechanical elements are needed for the "suspension", and the

composite hull is lighter than conventional materials. Of

course, this weight saving does not come at the expense of

safety, nor does it lead to cost price inflation. The weight

of a complete car equipped with the Dual Frame system varies

from 800 to 1150 kg, depending on the level of equipment

chosen. By way of comparison, a Ferrari 599 GTB Fiorano

officially weighs 1700 kg: that says it all!

Handling is progressive. As we have seen, the pneumatic

spheres adapt the car to the driving style (sporty, comfort)

and the road (low position on circuits or freeways, high

position on rough roads, plus all the intermediaries between

these two situations).

What future for Dual Frame?

Franco Sbarro naturally used the Dual Frame on numerous prototypes, including the two Sbarro Helios, the first cars to be equipped with it. Students at the Sbarro schools also used the Dual Frame for their various projects: proof that this system can be easily exploited. It was to be hoped that this ingenious system, which met the expectations of carmakers, would soon find its way to the general public. But the automotive industry was not interested: only the customers of Franco Sbarro and his students made use of the Dual Frame, which seems to me to be a great pity.

In brief

1- New chassis concept

2- Chassis in two separate parts

3- Chassis used notably on Espera prototypes